measuring zinc coating thickness|zinc coating thickness standard : convenience store Eddy current coating thickness gages (e.g. PosiTector 6000 N Series) look and operate like electronic magnetic gages. They are used to measure paint and coating thickness over all nonferrous metals. Like magnetic electronic gages, they commonly use a constant pressure probe and display results on an LCD. [/et_pb_toggle][et_pb_toggle title=”Vídeos – Ganhadores” op.

{plog:ftitle_list}

6 de out. de 2000 · 犯罪现场调查 第一季 CSI: Crime Scene Investigation Season 1 (2000) 编剧: 安东尼·E·祖克尔 主演: 乔治·艾德斯 / 艾瑞克·兹曼达 / 罗伯特·大卫·豪尔 / 保罗·吉尔福伊尔 / 乔雅·福克斯 / 更多. 类型: 剧情 / 悬疑 / 惊悚 / 犯罪 官方网站: www.cbs.com/primetime/csi 制片国家/地区: 美国 语言: 英语 首播: 2000-10-06 (美国) 季 .

When working with zinc coatings, metallography is mainly used to: Failure analysis; Measure the thickness of zinc coatings ; Analyze the microstructure of the coating and the base material ; Check adhesion; Fig. 1: Galvalume, .Coating Thickness vs. Coating Weight. The service life of zinc coatings is a linear function of the zinc coating thickness. However, zinc coating thickness alone can be deceiving when evaluating zinc applied by different processes. . Although an easy to use and highly versatile method for coating thickness measurement, the sample can be destroyed, if not using a coupon, and the low throughput often push people towards other methods to test . Eddy current coating thickness gages (e.g. PosiTector 6000 N Series) look and operate like electronic magnetic gages. They are used to measure paint and coating thickness over all nonferrous metals. Like magnetic electronic gages, they commonly use a constant pressure probe and display results on an LCD.

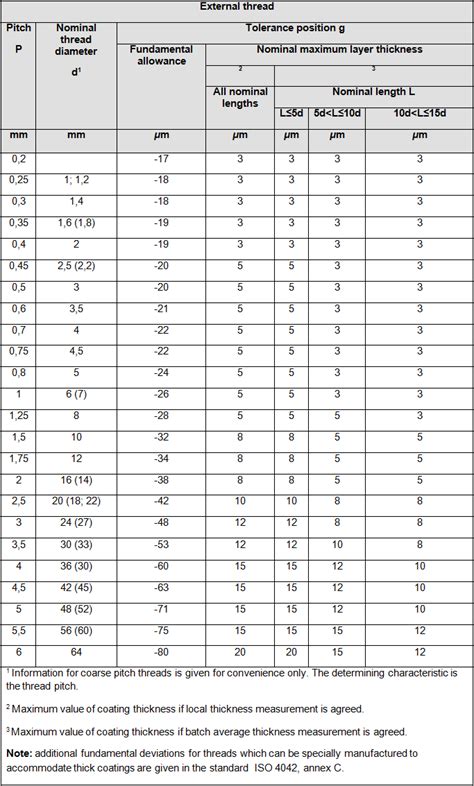

.mgz-element.jvhf3a7 .image-content{width:100%;text-align:center;}.mgz-element.jvhf3a7 .image-title{font-size:16px;}Fast Coating Thickness MeasurementsThe Elcometer 456 Coating Thickness Gauge enhances efficiency by providing 70+ dry film thickness readings per minute (140+ per minute when using a scan probe). The Elcometer 456 mil gage has multiple . The coating thickness is chosen on the basis of the type of coating system and the required protection. The ISO 10683 standard "Fasteners — Non-electrolytically applied zinc flake coating systems" includes a table which indicates the extent to which the level of corrosion protection depends on the thickness of the coating (by means of the duration of the salt .

How to Measure the Coating Thickness of a Duplex System. Measuring the thickness of duplex coating system layers with conventional instruments is challenging. Typically, a magnetic coating thickness gauge such as a PosiTector 6000 F1 or PosiTest DFT Ferrous is first used to measure the zinc thickness. The same instrument then measures the total .The PosiTector 6000 is a rugged, fully electronic coating thickness gauges use magnetic and eddy current principles to measure coating thickness on ALL metals, accurately and quickly . The PosiTector 6000 FNDS coating thickness gage measures individual thicknesses of both paint and zinc layers in a duplex coating system simultaneously. Accurate coating thickness measurement relies on several fundamental principles that professionals should understand. Let’s explore these principles: 1️⃣ Magnetic Induction: . Zinc-rich coatings: Zinc-rich coatings are made from a combination of zinc dust and resins. They are available in a variety of colors and finishes.Ultrasonic coating thickness gages (e.g. PosiTector 200) emit a high frequency sound pulse that travels into the coating via a coupling gel and reflects from ANY surface that is different in density.Paint thickness readings are obtained by measuring the time taken for the ultrasonic signal to propagate from the probe to the coating/substrate interface and back.

For thickness measurement tests , a minimum of five widely dispersed measurements are taken over the surface area of the specimen in order to represent the average specimen coating thickness. In order to test coating thickness of products whose surface area is greater than 160 in 2 (1032 cm 2 ),.

zinc plating thickness chart

The solution to getting the exact weight measurement of zinc coating on steel strip is to measure it during the production process rather than after. X-ray fluorescence (XRF) is an excellent technology to achieve the precision required for such measurements without costly and lengthy delays in production. . Incorporating coating thickness .AN034 Measuring the copper thickness in plated through-holes on PCBs 0.57 MB AN044 Determining the thickness of thermally sprayed aluminium (TSA) coatings on stainless steel 1.66 MB AN047 Measuring the zinc plating on nails with PHASCOPE® PMP10 0.52 MB AN091 Different ways to achieve valid measurement values and optimize measurement . The reason for this is that measuring thickness correctly and precisely is challenging. A G90 coating, for example, adds around 1.6 mils (0.0016 inches, or 42 microns) to the total thickness of the coated sheet. . While the coating includes around 8% to 10% iron, the density is somewhat greater than zinc and the coating thickness is slightly . One of the significant factors impacting GSM is the composition and thickness of the zinc coating. Different types of zinc coatings have varying densities, resulting in different GSM values. Additionally, the thickness of the zinc coating can directly influence the GSM measurement, as a thicker coating will result in a higher GSM value.

Coating Thickness Measurement Solutions Option #1. The PosiTector 6000 F Microprobe series consists of 3 gages which measure coatings up to 45 mils (1150 microns) thick, making them ideal for non-destructive measurement of .

A banana gauge is another tool used to measure coating thickness. Banana gauges can measure coating thickness in any position, without recalibration or interference from gravity. The most accurate gauge, .

Table 2 indicates that the galvanizing thickness of Coating Grade 100 is 100 microns or 3.9 mils. The weight of the galvanizing is 705 grams/square meter or 2.3 ounces/square foot. Methods for Measuring Galvanizing Weight or Thickness. Coating weight or thickness can be measured by one of four methods.

zinc coating thickness standard

zinc coating thickness conversion chart

micron to gm m2

The sheet metal supplier applies the zinc coating either by galvanic deposition or in a zinc dip bath. If the zinc coating thickness is uniform, the thickness of the subsequently applied paint coating can be measured using a conventional magnetic induction coating thickness measurement instrument.As indicated in Table 1, the total coating mass on heavier steel sections normally is a minimum of 600 grams of zinc per square meter of surface area (g/m²) which is equivalent to about 85μm thickness.

Measure the zinc coating at the number of spots specified in ASTM A123-02; Subtract the base metal reading from the gauge reading to obtain the thickness of the zinc. . Use a magnetic gauge such as the PosiTector 6000 F1 or PosiTest FM to measure the thickness of both the zinc and paint layers together. Subtract the zinc layer thickness to .

The PosiTector 6000 FNDS probe measures the individual thicknesses of both the paint and the zinc layers in a duplex coating system with a single reading. Duplex coating systems use a combination of two corrosion protection systems – typically paint or powder coating over galvanized steel (hot-dip, electro or zinc spray metallizing).

Coating thickness refers to the thickness of the final hot-dip galvanized coating, while coating weight refers to the amount of zinc for a given surface area. There are two different methods used to measure the coating thickness of hot-dip galvanized steel: a magnetic thickness gauge and optical microscopy. We are measuring manganese phosphate coating thickness on steel components. We are using instruments based on magnetic pulls. The thickness range of coating is 5 to 10 microns. We are getting average coating thickness in the range of 13-14 microns. My instrument has calibration standard of 70 microns. So we calibrate between 0 and 70 micron. Electrical wiring: zinc and nickel coatings are replacing older cadmium coatings How XRF measures coatings The Vanta handheld XRF analyzer can measure coating thickness from 0.00 to approximately 60.00 microns, depending on the material. X-rays are emitted from the analyzer, and they strike the sample, causing it to fluoresce.

Higher range probes are available for thicker coatings, with models available for measuring up to 63mm or 2.5in of coating thickness. Specialty probes are also available, for measuring rough or hot coatings, and for simultaneously measuring zinc and .Analysis of Zinc Coatings INTRODUCTION Zinc and zinc alloys are widely used in the automotive and fasteners industry. The outstanding corrosion resistance at . coating thickness measurement and composition analysis. Measurements can be made according to international test methods, ISO 3497 and ASTM B568. The FT110A uses a proportional counter .

iphone 6s vs samsung s7 edge drop test

iphone 6s water drop test

Resultado da Ksalsl. Sofia Novinha putinha quicando na piroca do Luis. 825.2k 100% 8min - 360p. Menina safada novinha do D4 cavalgando na pica amante. 152.9k 100% 1min 15sec - 360p. Novinha safada sentando. 104 2min - 1080p. Novinha cavalgando ao som do funk. 29.8k 82% 30sec - 360p.

measuring zinc coating thickness|zinc coating thickness standard